carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

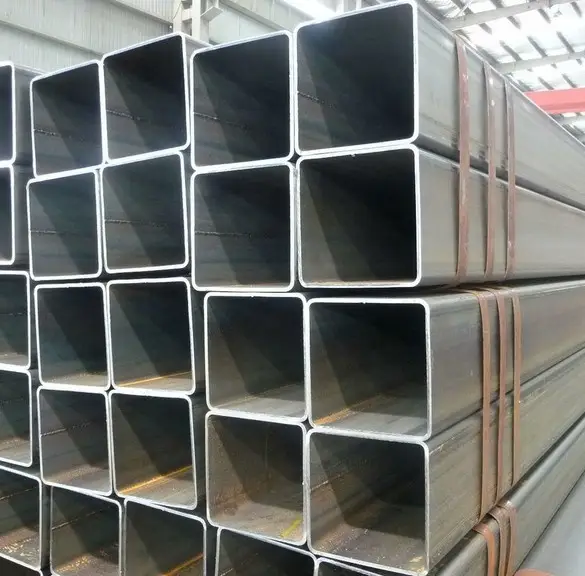

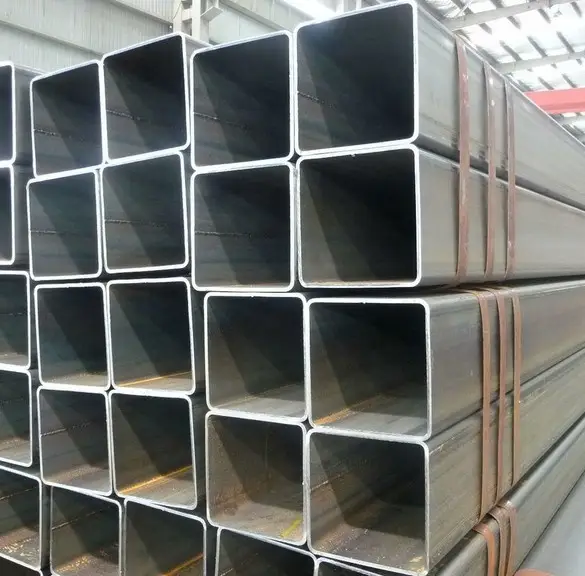

Square Hollow Section

Square hollow sections (SHS) is another popular type of structural steel tube that’s kind of a middle-man between RHS and CHS in terms of attributes, appearance and structural behavior.

SHS features a flat surface that’s also economical for joining and welding, with clean lines and minimal edge preparation required.

SHS also features attributes of CHS, with its symmetrical appearance, formed in equal-sided square hollow sections – as opposed to circular sections.

SHS provides an ideal balance between strength, functionality and aesthetic appearance for a multitude of applications that require all three aspects.

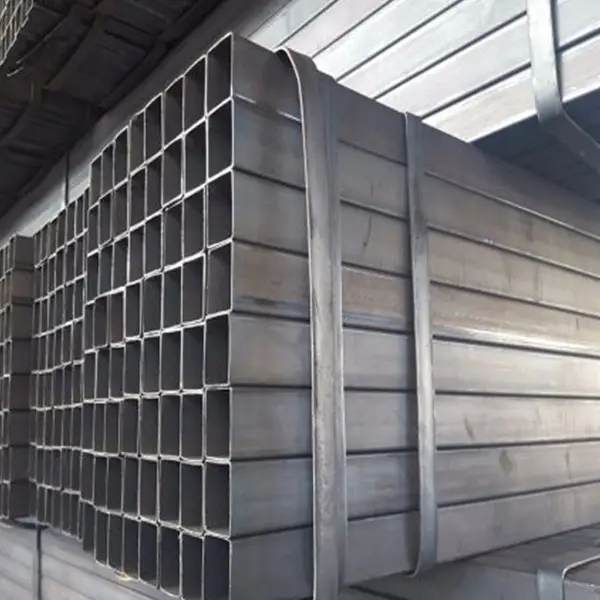

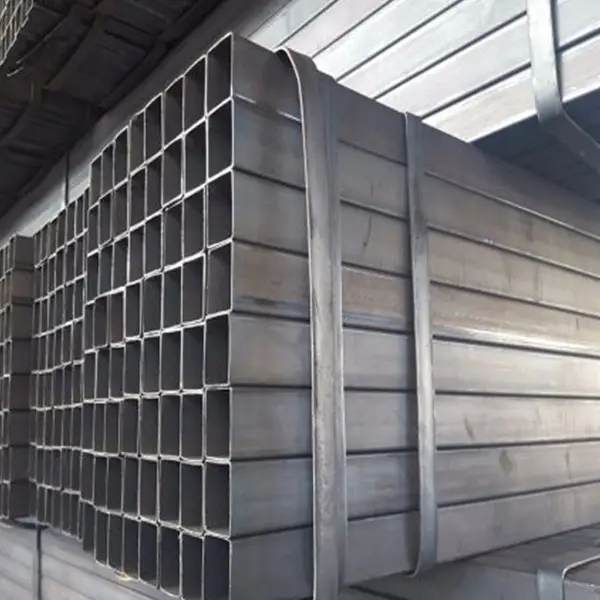

Rectangular Hollow Sections

Rectangular hollow sections (RHS) is a popular choice for mechanical, structural and construction applications. This is due to the flat surface resulting in a structural solution that is more economical for joining and various other types of fabrication works.

Due to the rectangular shape of this type of hollow section, when joining to other flat surfaces sections only need to be straight cut. RHS requires minimal edge preparation for welding or joining.

RHS can also be used for architectural aesthetics due to possessing clean lines alongside structural strength.

Available Size Ranges:

— 21.30 OD to 323.9 OD in Circular tubes

– 20 x 20 – 250 x 250mm in Square Sections

– 40 x 20 -300 x 200 in Rectangular Sections

Thickness Range : 1.50mm to 12.50mm.

Available Lengths:

– 6 metres, 7.50 Metres and/or 12 metres standard

– Any length made to order

|

Rectangular Hollow Section |

|

Square Hollow Section |

|||||

|

Size |

Thickness |

|

Size |

Thickness |

|

Size |

Thickness |

|

mm |

mm |

|

mm |

mm |

|

mm |

mm |

|

50 X 25 |

2.0 |

|

120 X 40 |

3.0 |

|

20 x 20 |

2.0 |

|

50 X 25 |

2.5 |

|

120 X 40 |

3.6 |

|

20 x 20 |

2.5 |

|

50 X 25 |

3.0 |

|

120 X 40 |

4.0 |

|

25 x 25 |

2.0 |

|

50 X 30 |

2.5 |

|

120 X 40 |

5.0 |

|

25 x 25 |

2.5 |

|

50 X 30 |

3.0 |

|

120 X 40 |

6.0 |

|

25 x 25 |

3.0 |

|

50 X 30 |

3.2 |

|

120 X 40 |

6.3 |

|

30 x 30 |

2.5 |

|

50 X 30 |

4.0 |

|

120 X 60 |

3.0 |

|

30 x 30 |

3.0 |

|

60 X 40 |

2.5 |

|

120 X 60 |

3.6 |

|

40 x 40 |

2.0 |

|

60 X 40 |

3.0 |

|

120 X 60 |

4.0 |

|

40 x 40 |

2.5 |

|

60 X 40 |

3.2 |

|

120 X 60 |

5.0 |

|

40 x 40 |

3.0 |

|

60 X 40 |

4.0 |

|

120 X 60 |

6.0 |

|

40 x 40 |

4.0 |

|

80 X 40 |

3.0 |

|

120 X 60 |

6.3 |

|

50 x 50 |

2.0 |

|

80 X 40 |

3.2 |

|

120 X 80 |

3.0 |

|

50 x 50 |

2.5 |

|

80 X 40 |

4.0 |

|

120 X 80 |

4.0 |

|

50 x 50 |

3.0 |

|

80 X 60 |

2.5 |

|

120 X 80 |

5.0 |

|

50 x 50 |

4.0 |

|

80 X 60 |

3.0 |

|

120 X 80 |

6.0 |

|

50 x 50 |

5.0 |

|

80 X 60 |

3.6 |

|

120 X 80 |

6.3 |

|

60 x 60 |

3.0 |

|

80 X 60 |

4.0 |

|

150 X100 |

3.0 |

|

60 x 60 |

4.0 |

|

80 X 60 |

5.0 |

|

150 X100 |

4.0 |

|

60 x 60 |

5.0 |

|

90 X 50 |

2.5 |

|

150 X100 |

5.0 |

|

70 x 70 |

3.0 |

|

90 X 50 |

3.0 |

|

150 X100 |

6.0 |

|

70 x 70 |

3.6 |

|

90 X 50 |

3.6 |

|

150 X100 |

6.3 |

|

70 x 70 |

5.0 |

|

90 X 50 |

4.0 |

|

160 X 80 |

3.0 |

|

80 x 80 |

3.0 |

|

90 X 50 |

5.0 |

|

160 X 80 |

4.0 |

|

80 x 80 |

3.6 |

|

100 X 40 |

3.0 |

|

160 X 80 |

5.0 |

|

80 x 80 |

5.0 |

|

100 X 40 |

3.6 |

|

160 X 80 |

6.0 |

|

80 x 80 |

6.0 |

|

100 X 40 |

4.0 |

|

160 X 80 |

6.3 |

|

90 x 90 |

3.0 |

|

100 X 40 |

5.0 |

|

200 X 100 |

4.0 |

|

90 x 90 |

3.6 |

|

100 X 50 |

3.0 |

|

200 X 100 |

5.0 |

|

90 x 90 |

5.0 |

|

100 X 50 |

3.6 |

|

200 X 100 |

6.0 |

|

90 x 90 |

6.0 |

|

100 X 50 |

4.0 |

|

200 X 100 |

6.3 |

|

100 x 100 |

4.0 |

|

100 X 50 |

5.0 |

|

200 X 100 |

8.0 |

|

100 x 100 |

5.0 |

|

100 X 50 |

6.0 |

|

200 X 100 |

10.0 |

|

100 x 100 |

6.0 |

|

100 X 50 |

6.3 |

|

200 X 100 |

12.5 |

|

100 x 100 |

8.0 |

|

100 X 60 |

3.0 |

|

200 X 100 |

16.0 |

|

100 x 100 |

10.0 |

|

100 X 60 |

3.6 |

|

250 X 150 |

6.3 |

|

120 x 120 |

5.0 |

|

100 X 60 |

4.0 |

|

250 X 150 |

8.0 |

|

120 x 120 |

6.0 |

|

100 X 60 |

5.0 |

|

250 X 150 |

10.0 |

|

120 x 120 |

8.0 |

|

100 X 60 |

6.0 |

|

250 X 150 |

12.5 |

|

120 x 120 |

10.0 |

|

100 X 60 |

6.3 |

|

250 X 150 |

16.0 |

|

150 x 150 |

5.0 |

|

100 X 80 |

3.0 |

|

300 X 200 |

6.3 |

|

150 x 150 |

6.0 |

|

100 X 80 |

3.6 |

|

300 X 200 |

8.0 |

|

150 x 150 |

8.0 |

|

100 X 80 |

4.0 |

|

300 X 200 |

10.0 |

|

150 x 150 |

10.0 |

|

100 X 80 |

5.0 |

|

300 X 200 |

12.5 |

|

180 x 180 |

6.0 |

|

100 X 80 |

6.0 |

|

300 X 200 |

16.0 |

|

180 x 180 |

8.0 |

|

100 X 80 |

6.3 |

|

400 X 200 |

10.0 |

|

180 x 180 |

10.0 |

|

|

|

|

400 X 200 |

12.5 |

|

180 x 180 |

12.5 |

|

|

|

|

400 X 200 |

16.0 |

|

200 x 200 |

6.0 |

|

|

|

|

450 X 250 |

10.0 |

|

200 x 200 |

8.0 |

|

|

|

|

450 X 250 |

12.5 |

|

200 x 200 |

10.0 |

|

|

|

|

450 X 250 |

16.0 |

|

200 x 200 |

12.5 |

|

|

|

|

|

|

|

250 x 250 |

8.0 |

|

|

|

|

|

|

|

250 x 250 |

10.0 |

|

|

|

|

|

|

|

250 x 250 |

12.5 |

|

|

|

|

|

|

|

300 x 300 |

8.0 |

|

|

|

|

|

|

|

300 x 300 |

10.0 |

|

|

|

|

|

|

|

300 x 300 |

12.5 |

|

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16 .0 -18.0 |

- |

|

202 |

≤0 .15 |

≤l.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤l.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

|

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0- 3.0 |

|

316L |

≤0 .03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 - 15.0 |

16 .0 -1 8.0 |

2.0 - 3.0 |

|

321 |

≤ 0 .08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -1 9.0 |

- |

|

630 |

≤ 0 .07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤ 2 .0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤ 0.03 |

0.19 -0. 22 |

0. 24 -0 . 26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤ 0.03 |

≤0.60 |

16.0 -18.0 |

- |